How GV Group (Gate Ventures) injected fresh value into its supply chains

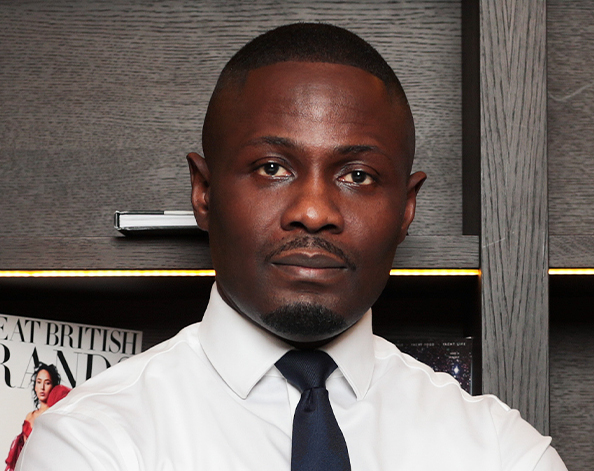

Last-mile delivery leader GV Group (Gate Ventures) was particularly affected by supply chain disruptions. CEO Tevin Tobun explains how the company used this difficult period as an opportunity to optimise its business model – and came out with a competitive advantage.

GV Group is one of the UK’s leading independently owned food logistics specialists with a global footprint spanning across the UK, South America and Africa. The business focuses its operations within the education, social, healthcare, retail, and business and industry sectors. It has more than 20 years’ experience servicing FTSE 100 companies and delivering for the largest FMCG companies globally.

Given the nature of this logistics business, it faced unprecedented challenges due to the supply-side disruption created by the pandemic. In this latest insight, Osian Rees, Client Coverage for Investec Private Companies, spoke to GV Group's CEO Tevin Tobun about how the group not only successfully navigated headwinds but injected fresh agility and dynamism into its business model – which has allowed it to capture market share.

Tevin also discussed the challenging trade-off between attaining sustainability versus convenience, and empowerment as a natural barrier to employee turnover.

Going the extra mile

GV Group operates in one of the most important areas of the supply chain: last-mile delivery. No matter how complex a chain, this is the final crucial step in the process – where the product arrives at the doorstep. It is the last step in the consumer experience and critical for satisfaction levels.

The firm has been an industry leader in delivering time-sensitive, heat-controlled logistical excellence in remote areas. For example, within the education sector, one of GV’s companies, Platebox, delivers over 10 million meals to schools across the UK, ensuring meals are delivered on time and at just the right temperature so children can enjoy healthy nutritious lunches and learn.

But against the current challenging backdrop, the crucial question was: could this best-in-class business keep its supply lines functioning under acutely challenging conditions?

Tevin explained that before the pandemic, even last-mile supply chains were getting more predictable and easier to forecast. This was increasingly supported by technology, creating ever more efficient and seamless logistical chains.

“Human nature may be unpredictable, but human patterns are surprisingly easy to forecast and plan supply chains around. However, this ‘steady state’ of supply chain management was severely disrupted by the pandemic,” he said.

This new landscape demanded a radical approach. Tevin said: “When the pandemic struck, we literally had to tear up the rule book. It was the ultimate stress test that would reveal how well we had integrated responsiveness and flexibility into our business model and organisational culture.

“In reacting to the rapidly changing environment, we allowed our people to understand the baseline of their objectives and devolved decision-making. This meant empowering our regional offices. As the scale of the pandemic’s complexity emerged, we knew lockdowns would not be the same in London as in Leicester, never mind Nigeria or Guyana – our departments needed the bandwidth to make decisions swiftly and exercise agility.”

Protecting margins

Cascading the decision-making and letting this ethos flow through the company forged a more dynamic culture, according to Tevin: “We created contingency plans and new processes with account managers and logistics teams. We were able to map this across the four core areas of our business. We also created new dialogues and collaborative engagement to solve common problems with our clients. These threads of enhanced engagement, dynamism and agility across our company will leave a positive legacy for decades to come,” he said.

For any business operating supply chains in this new volatile landscape and seeking to protect margins, Tevin said it was vital to ensure a margin of safety and operational headroom. To do so, he advocated having more parameters around operational expenses, better spending discipline, and continually weighing up the value of engagement with weekly analysis, factoring in as much data and analytical tools as possible, combined with qualitative feedback.

“By streamlining our processes and injecting fresh value into our own chain, we not only protected our margins, but as other businesses stagnated or struggled to cope, we realised we had created a competitive advantage,” he added.

This Tevin believes will leave an opportunity for growth as the industry sees an elevated period of consolidation and winners and losers emerge.

Tevin also sees technology playing an increasing role in the new landscape. The firm recently invested in ROUT’D, a nimble delivery platform which helps businesses plan and forecast more accurately.

“In this space, all businesses must have the ability to be flexible, which is essential in the current climate – and technology is an enabler,” he said.

Sustainability versus convenience

The pandemic has created a historic opportunity to build back better and re-imagine supply chains. Within this evolution, Tevin believes ESG will be at the forefront of change.

“This change is not transitory. Attitudes have shifted and the expectations around delivery times are higher. At the same time, there is a competing drive for ESG at both corporate and consumer levels,” he said.

Due to the pressure on supply chains, many firms have been focusing on steadying the ships and addressing logistical pain points. However, Tevin explained that driven by political and public will, underlined by COP 26, ESG will drive the direction of travel for supply chains.

Yet he also said this might run contrary to current behaviours, where consumers are consistently ordering single purchase items, which leads to obvious inefficiencies and larger carbon footprints.

“The shift to working from home has reset expectations around convenience. However, if we are to protect the planet, we need to think about how we work with clients to engage with consumers and create more sustainable supply chains as well as buying behaviours.”

“The shift to working from home has reset expectations around convenience. As people have stayed at home, they have adjusted their expectations around receiving goods. Previously, they had to consider a day when they might be out of office, now they demand next day delivery. However, if we are to protect the planet, we need to think about how we work with clients to engage with consumers and create more sustainable supply chains as well as buying behaviours.

“This might mean amalgamating or consolidating orders, if are going to move the dial on sustainability. Technology and analytics will also be crucial,” he said.

Tevin is already working on his long-term strategy and a zero-emission fleet of electric vehicles to ensure GV Group is ahead of the curve on emissions.

Human connection

Tevin said the supply chain crisis had revealed that the most crucial cog in his operations was, overwhelmingly, people. He explained the pandemic had given management a unique aperture into the lives of GV Group’s employees, as the world moved away from structured to unstructured days and new hybrid ways of working.

“When you get a window into the everyday struggles people face it binds you closer together. We have always been a people business, but the pandemic has allowed us to have a deeper human connection. We now give people more room to ensure they look after the personal aspects of their lives while giving them more control in the workplace. It is all around trust – we have parameters around KPIs, but ultimately, it is down to trusting a person to get the job done,” he said.

High staff turnover is one of the big challenges facing businesses operating in supply chain management, as well as inflationary pressures, Tevin explained.

“By creating an empowering business culture where people have good work/life balance, you can build a natural barrier to high turnover.”

“By creating an empowering business culture where people have good work/life balance, you can build a natural barrier to high turnover. Having easily transferable skills also allows your employees to work across new areas of the business without feeling the need to seek new employment,” he said.

Tevin added that a deeper human connection has been forged with clients and this makes GV Group a far more resilient business moving forward.

“During the pandemic, we collaborated and engaged with clients. We got a better understanding of their business and they of ours. These connections ensure we have emerged from the pandemic stronger and more resilient than ever,” he said.

Founder and Family Business Network

Join our Founder and Family Business Network to hear about other similar stories.

Browse articles in